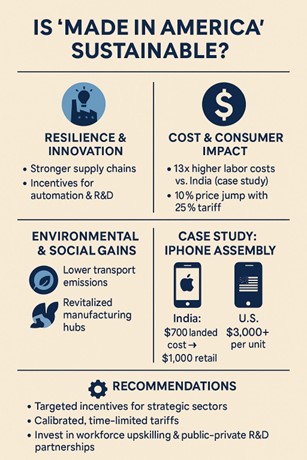

Over the past year I’ve dug into the pros and cons of onshoring U.S. manufacturing—and the results are nuanced:

1️⃣ Resilience & Innovation

• Stronger supply chains

• Incentives for automation & R&D

2️⃣ Cost & Consumer Impact

• 13× higher labor costs vs. India (iPhone case study!)

• Potential 10% price jump if U.S. imposes a 25% tariff on India-made devices

3️⃣ Environmental & Social Gains

• Lower transport emissions

• Revitalized American manufacturing hubs

• But automation limits broad-based job growth

🔎 Case in Point: Apple iPhone Assembly

• India w/ PLI incentives: ∼$700 landed cost → $1,000 retail

• Add 25% U.S. tariff: landed cost jumps to $875 → $1,100 retail

• U.S. assembly without tariffs: projected >$3,000/unit 😮

⚖️ Bottom Line & Recommendations

• Targeted incentives for strategic sectors (semiconductors, clean energy)

• Calibrated, time-limited tariffs—not blanket duties

• Invest in workforce upskilling & public-private R&D partnerships

What are your thoughts on balancing cost vs. resilience in global manufacturing? 💬👇